Scanning and CMM Inspection Services in India | Soham Foundry Tools

Soham Foundry Tools stands as a leading Scanning and CMM Inspection Services in India and Service Providers in India to various industries through advanced technological solutions. We apply accuracy-focused measures to develop custom-made CMM Inspection Services that fulfill our client requirements. We provide portable CMM inspection services for on-site applications as well as Fix Bed CMM Mounted Scanner Inspection Services for stationary and precise measurement requirements.

As the Scanning and CMM Inspection Services in India, we enable businesses to access state-of-the-art CMM Inspection - 3D Scanning Services for the delivery of advanced CMM Measurement and Inspection Services. We deliver top-quality 3D Scanning & CMM Inspection Services which help clients obtain immediate feedback to adjust their designs, build prototypes, and optimize their products.

About the Scanning and CMM Inspection Services in India:

Advanced technology through scanning and Coordinate Measuring Machine (CMM) inspection services allows measurement and inspection of part dimensional characteristics and geometric shapes. The assessments guarantee component fulfillment of quality requirements and precise manufacturing tolerances which improves product accuracy.

Scanning and CMM Inspection Service Providers in India, we demonstrate superior expertise in CMM Inspection Service & Its Application for the automotive and aerospace sectors as well as manufacturing. Our Onsite CMM Inspection Services conduct rapid accurate assessments for those industries that prefer local assessment instead of part transport so they can save money over time. Our Inspection & Reverse Engineering Service helps industry clients reproduce complex parts using tight tolerance measurements.

Types of Scanning and CMM Inspection Services:

Some of the top Scanning and CMM Inspection Services in India present an extensive range of high-grade services that are flexible enough to be applied in all types as follows:

- Portable CMM Inspection Service: When you need to measure large and heavy parts that cannot move to a stationary machine this method works best. The service delivers precise live data simultaneously with its lightweight structure.

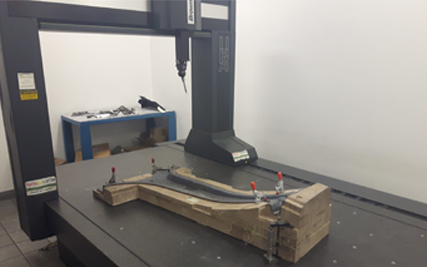

- Fix Bed CMM Mounted Scanner Inspection Services: This service uses a scanning system installed on a specific CMM platform to precisely measure part dimensions in three dimensions. The service gives precise measurements when the part sits securely on the bed.

- 3D Scanning & CMM Inspection Services: Pond offers this service for product development and examines how parts work together in their expected locations. The method suits capturing intricate surface shapes and precise shapes.

- Onsite CMM Inspection Services: The CMM unit travels to your facility to take measurements which reduces part transport expenses and delays production. The service fits well with organizations seeking quick measurement support at their required times.

- Inspection & Reverse Engineering Service: Customers trust this service to duplicate parts when redesigning them. Our service fuses CMM checks with reverse engineering methods to develop precise CAD models from physical parts.

Specifications of Scanning and CMM Inspection Services

We have added below a technical sheet of our Scanning and CMM Inspection Services that provides more technical information such as:

| Specification | Details |

|---|---|

| Scan Area |

|

| Measurement Speed |

|

| Material Compatibility |

|

| Inspection Features |

|

| Scanning Time |

|

Benefits of Scanning and CMM Inspection Services

Being one of the very best in the category of Scanning and CMM Inspection Service Providers in India, all types are made using advanced technology and hence offer a variety of benefits such as:

- Accuracy and Precision: CMM inspection along with scanning technologies delivers very precise measurements thus allowing manufacturers to determine if their parts adhere to exact specifications without considerable errors for quality control needs.

- Time Efficiency: These services shorten manual measurement procedures which enables swifter production processes while quickening the process of detecting design errors or specification deviation.

- Cost-Effective: CMM inspection along with scanning helps businesses reduce expenses for manual work as well as material waste to achieve better production rates.

- Versatility: Looking at diverse materials and sizes of parts is possible with Scanning and CMM systems which makes them appropriate for aerospace industries along with manufacturing sectors and automotive production.

- Data-Driven Decision Making: Contemporary technological data allows analysis of produced information to track patterns that aid future design development alongside manufacturing system enhancement and data-driven choices.

Applications of Scanning and CMM Inspection Services

Scanning and CMM Inspection Services and Service Providers in India, our highly demanded by multiple types of applications and are used for improving performance, such as:

- Reverse Engineering: The digital models produced by scanning and CMM inspection enable replication or redesign of existing parts without requiring original Computer-Aided Design information that proves advantageous for component modifications.

- Quality Control & Assurance: During production, these inspection systems track part and assembly precision to discover deviations which ensures excellent quality standards.

- Prototype Testing: The combination of Scanning and CMM inspection monitors prototype part dimensions for manufacturing readiness which eliminates production costs and delayed production.

- Assembly Line Inspection: Automated assembly lines can use integrated Scanning and CMM systems for production quality control which enables both higher efficiency and free-of-error manufacturing.

- Tool and Mold Calibration: These inspection tools provide continuous monitoring of production tools to preserve their shape integrity thus maintaining high-quality production outputs.

Soham Foundry Tools operates expert Scanning and CMM Inspection Services in India and Service Providers in India. We deliver dependable inspection solutions through our emphasis on advanced technology and rigorous quality assurance procedures which enable them to meet the most stringent standards. We stand as a reliable service company that delivers fast solutions while satisfying its clients through precise scanning and CMM inspection services which help manufacturers optimize our production methods and product excellence.

FAQ

Ans: A CMM (coordinate measuring machine) inspection is where objects for products can be inspected for quality and measured.

Ans: A probe on the CMM touches the object's surface, sending signals to the machine's computer. The computer calculates the object's dimensions and position.